Printing the future: Students and professors tackle real-world problems in their research

Randolph’s Summer Research Program is a competitive, paid program that pairs students with faculty members to conduct research in their areas of interest. This story is part of an ongoing series featuring their work on campus this summer.

As some industries across the country face a shortage of key raw materials—scrap metal, for instance, which is vital to steel production—a team at Randolph College is exploring ways they can adapt.

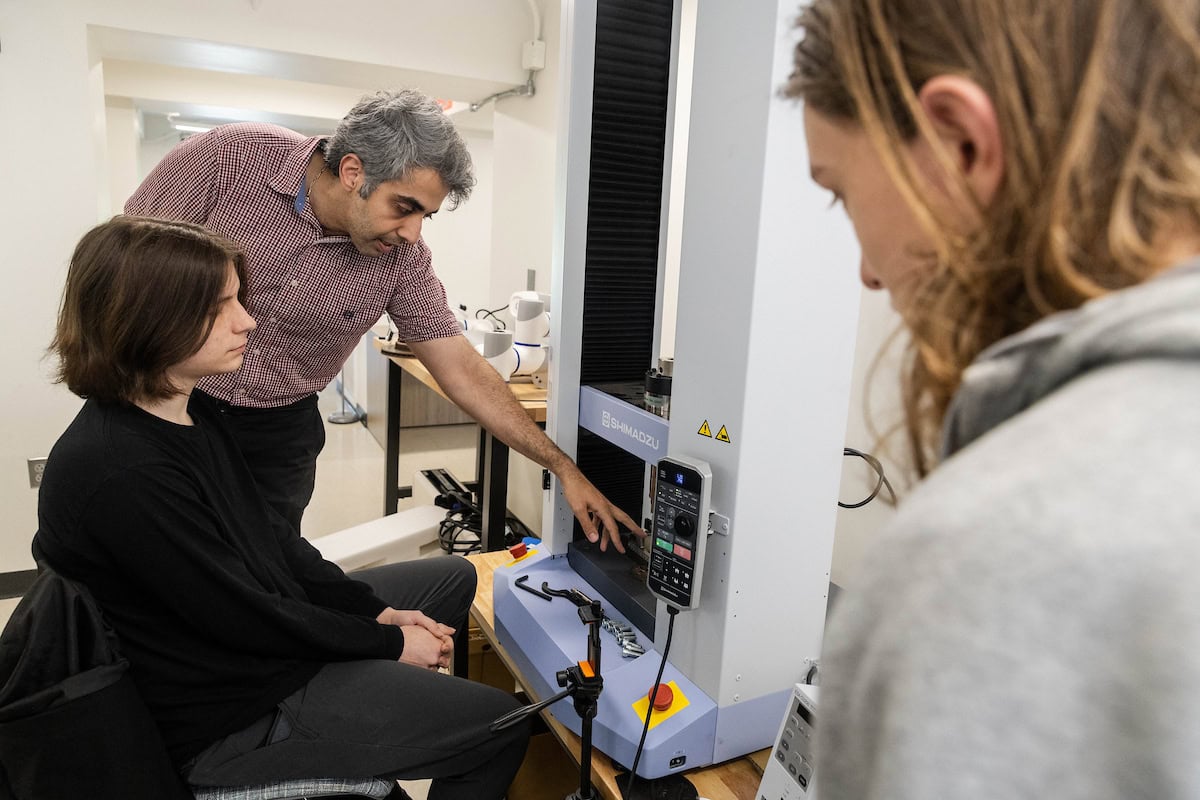

The project, led by professors Siavash Sattar and Peter Sheldon, investigates how the layout and structural design of 3D-printed fiber-reinforced polymer composites affect their mechanical and fracture behavior.

They are working with student researchers Jacey Wright ’28 and Morgan Sikes ’28, both robotics and mechatronics engineering majors who are contributing to the experimental design, fabrication, testing, and analysis of the processes.

The research focuses on structures created using fused filament fabrication, a 3D printing process that builds objects layer by layer, aiming to optimize their performance for potential use in load-bearing applications.

“There are so many complexities to this and how it could potentially help our current climate, with something like steel manufacturing and other real-world materials that we’re starting to run out of,” Sikes said. “This could help sustain the world for a lot longer.”

Using the College’s 3D printing systems, they are fabricating composite specimens with innovative design features and then testing their strength.

“We’re studying how the way a material is built—in this case, the internal structure of 3D-printed fiber-reinforced composites—affects its strength and performance under different loading conditions,” Sattar said. “By considering different printing strategies, like how the layers are arranged, we can find out which designs lead to stronger, more reliable components.”

Or, as Sikes put it more simply: “We’re making stuff until it works. There’s a lot of success and failure, and that’s how we learn.”

They’re also designing and fabricating composite sandwich structures featuring 3D-printed cores with varied core architectures—honeycomb, hexagonal, and rectangular, to name a few—to study their mechanical response.

“Sandwich structures are widely used in aerospace due to their high stiffness-to-weight ratio,” explained Sattar. “Traditionally, these systems rely on foam cores. We’re replacing the foam with glass fiber-reinforced polymer composite cores to evaluate their potential as a high-performance alternative with improved strength, durability, and design flexibility.”

For Wright, a rising sophomore majoring in robotics and mechatronics engineering, the opportunity to engage in hands-on research with real-world applications was a key reason for joining the project.

“In high school, we were always told to get involved early, and Summer Research was the ideal opportunity,” he said. “What’s exciting is that this isn’t just busywork. We’re part of something that could have a real impact.”

Tags: engineering, robotics, robotics and mechatronics, robotics and mechatronics engineering, summer research 2025